Copper wire rod:

Copper single wire:

* soft

** hard

Copper multi-wires 6 to 24 wires:

Strands and highly flexible ropes from 0.01 to 35 mm².

Constructions:

Concentric:

Copper braiding wires from 3 to 16 wires:

Special Products:

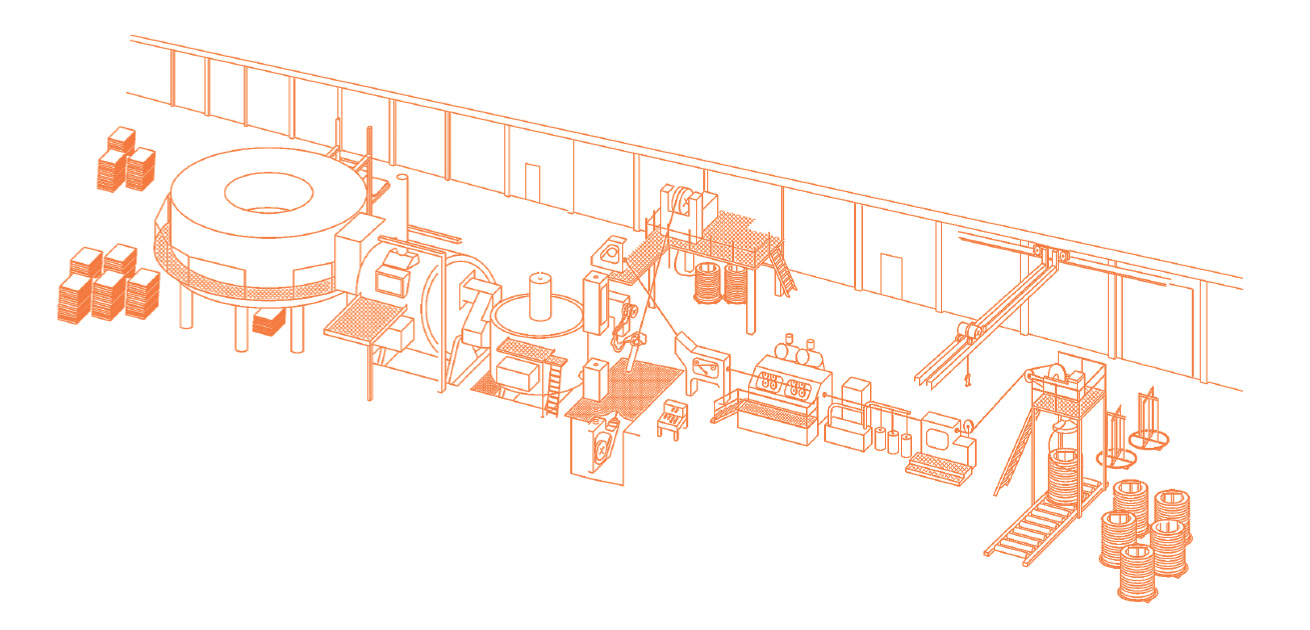

Dip-forming line

Cathode input

Preheating oven

Melting furnace

Holding furnace

Crucible

Scraping

Mother rod

Dancers

Dancers

Rolling mill

Winder

1. cathode input

2. preheating oven

3. melting furnace

4. holding furnace

5. crucible

6. shaving

7. mother rod

8. & 9. dancers

10. rolling mill

11. winder

Manufacturing Process

Decisive for the image of LACROIX + KRESS as a manufacturer of superior copper wires is the internationally recognised “dip-forming” process, which allows the production of a high-quality, oxygen-free dip-formed wire rod (Cu-OF1, according to EN 1977).

The production of our copper wire rod begins with the melting of copper or the selection of the electrolytic copper cathodes. This process technology allows a continuous production of copper rod in long lengths and offers considerable quality advantages compared to conventional oxygen-containing cast wire rod such as Cu-ETP1 (E-Cu58) or deoxidised, phosphorus-containing copper grades such as Cu-PHCE (SE- or SF-Cu58). The very smooth surface, the good formability, drawability and resistance against hydrogen embrittlement are especially notable. Due to its excellent surface quality, this pre-material is particularly suitable for further forming processes, but also for galvanic surface treatments or plating. In addition, LACROIX + KRESS also produces silver alloy wire rod CuAg (OF). Dip-formed wire rod is produced in diameters of 8.0 mm, 10.0 mm, 12.5 mm and 14 mm.

“DIP-forming”

Production Process

Dip-formed wire rod is available in different qualities

suitable for fine wire drawing

highly hydrogen-resistant

silver alloy

We can offer you the following special types of dip-formed wire rod:

Dip-formed wire rod TWF, finely drawable quality: For drawing applications in the finest and ultra-fine range, we manufacture a fine wire quality, drawable ≤ 0.05mm.

Dip-formed wire rod TWH with increased resistance against hydrogen embrittlement: Our highly hydrogen-resistant dip-formed wire rod offers excellent welding and brazing properties. This type corresponds to the high-purity quality Cu-OFE (EN 1977) and meets the requirement of the reverse bend test (NB > 10 according to ISO 2626, EN 1977, ASTM-B 170 Grade 1).

Dip-formed wire rod TWS, silver alloy: Dip-formed silver alloy rod from LACROIX + KRESS is characterized by a significantly increased recrystallization temperature and high tensile strength after drawing, depending on the silver content. The other characteristic properties of oxygen-free copper are not changed. CuAg (OF) is supplied with silver contents of 0.01 to 0.10 %, depending on requirements.

Our employee Alexander fills the anode baskets with nickel pellets in protective equipment at an electroplating line.

The line is located in a specially equipped plating room with acid-resistant floor coating to protect the environment.

Galvanic

nickel-plating line

Basics /

Applications /

Dimensions

The Lacroix + Kress factory Neunburg

is a manufacturer of bare, tinned, nickel-plated and silver-plated multi-wires, strands and ropes. Our product range includes bare and tinned conductors in bunched, concentric, unilay or rope lay constructions with single wire diameters from 0.05 to 0.70 mm (AWG 44 – AWG 21) up to a cross-section of 35 mm². Silver-plated and nickel-plated multi-wires and strands are produced with single wire diameters from 0.05 to 0.50 mm (AWG 44 – AWG 24). Specialties include braiding or shielding wires wound on Wardwell or Spirka spools for direct use in braiding machines. Our products are manufactured according to national and international standards and, of course, according to our customers’ specifications. This means that we can offer conductors ideally suited for a wide variety of applications and cable types.

Lacroix + Kress has considerable production capacities in the Neunburg plant, consisting of breakdown drawing machines, electroplating lines, multi-wire drawing lines, single and double twist bunching machines and tubular stranding machines.

Round copper wires bare, tin-, silver- and nickel-plated

The starting product of our copper wires is an oxygen-free copper rod Cu-OF1 produced in our dip-forming plant or a wire rod Cu-ETP1 according to EN 1977 purchased from international manufacturers.

A dip-formed silver alloy rod CuAg (OF) with a silver content of 0.01 to 0.10 % or CuSn (ETP) with 0.3 % tin can also be used as a starting material for our drawing shops.

In our wire drawing department these different pre-materials are drawn on breakdown machines to diameters between 1.0 and 7.0 mm and on our medium and fine wire drawing machines down to 0.05 mm.

These wires can be plated on our galvanic lines with tin, silver or nickel with different layers.